Inventory Management as Part Of the Overall Supply Chain

Inventory management is a key element of the supply chain. It is sometimes confused with other related processes and practices of the supply chain ecosystem. Inventory Management is the tracking of inventory from raw materials to manufacturers, to finished goods, to distributors, warehouses (wholesaler or retailer), and from these facilities to a point of sale (end customer). The goal of inventory management is to have the right products in the right place at the right time.

What is Inventory Management?

To better understand Inventory Management, it is helpful to distinguish between other related processes:

Inventory management controls all stock within a company.

Supply chain management manages the end-to-end process from raw materials supplier to manufacturer to delivering the product to the end customer

Warehouse management is a part of inventory control and focuses on stock in a specific location.

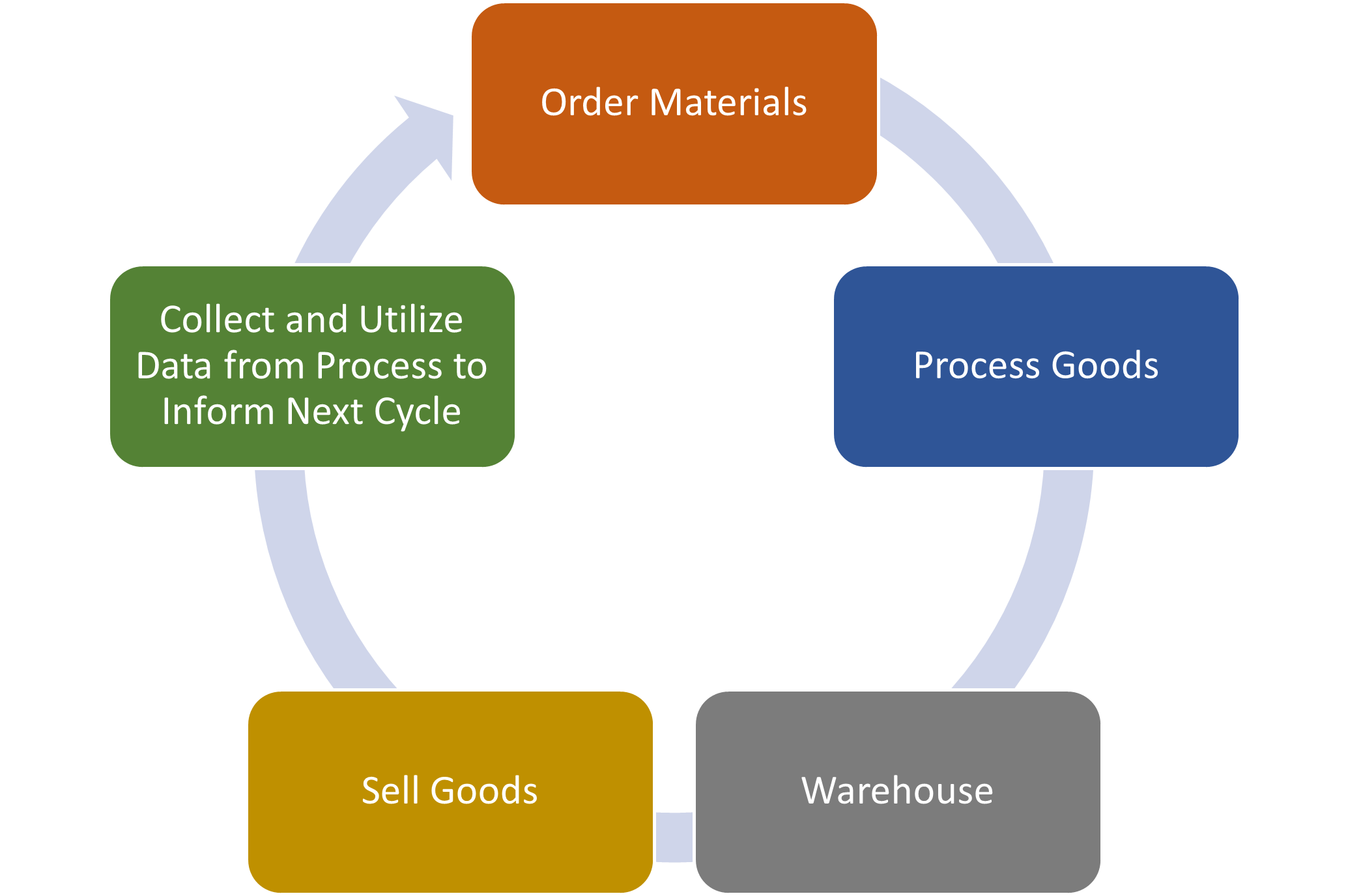

Inventory (see diagram below) is all the raw materials, components, and finished products held by a company with the intention of being sold. Inventory Management refers to the entire process of tracking a company’s inventory through all stages of ordering, warehousing, processing, and selling.

How Does Inventory Management Work?

Inventory Management, a critical component of Supply Chain Management, is the tracking of availability of goods across the company supply chain, through manufacturing facilities, warehouses, and finally to the consumer. The purpose of Inventory Management is to ensure that inventory is as efficient as possible, and a company avoids both excesses and shortages. To do this effectively requires a company to have inventory visibility - knowing the timing of when to order, the amount to order, and how and where to house the supply until it is used or sold.

Inventory Management Lifecycle

Why Is Inventory Management Important?

Inventory management is vital to a company’s well-being because it is where all components of the supply chain come together. Having too little inventory at a certain time may cause customer dissatisfaction if products are delayed or not available. Having too much inventory also presents problems like figuring out how to store the excess goods, the risk of items being stolen, damaged, or spoiled. All companies must find the right balance between having too little or too much inventory.

Conducting an Inventory Management Assessment can help a business evaluate their needs and align their strategy accordingly. The following is a case study for a T Exponents Large Retailer Inventory Management Assessment project:

Large Retailer Inventory Management Assessment & Gap Closure - T Exponents Case Study

Types of Inventory Management

In general, there are three types of inventory management systems:

Manual Inventory System - memory counting and manual recording on paper, in spreadsheets etc.

Periodic Inventory System - includes both manual and computerized counts and involves measuring inventory at the beginning of a period, adding, and removing stock, and taking the difference between the opening and closing data from the period to assess inventory.

Perpetual Inventory System - provides real-time inventory data and can track inventory through the entire lifecycle of manufacture, storage, and shipment to retailer or consumer.

Ensuring More Efficient Supply Chain Inventory Management

There are several ways of ensuring more efficient supply chain inventory management. Some of the most important and effective ones are:

Maintaining Supplies: To ensure that the supply of critical goods for your organization remains uninterrupted.

Re-assessing Strategies and Suppliers: Assessing and changing strategies to reduce the supply chain and inventory management risk to its minimum. See the following case study for an example of a T Exponents Supplier Replacement case study.

Multinational Corporation Strategic Vendor/Supplier Replacement - T Exponents Case Study

Accepting Technology and Digital Changes: Research and implementation of the latest technology and advanced digital platforms can help companies in more accurate forecasting. These advanced inventories and warehouses for management can help companies track important metrics and improve the overall supply chain.

Culture of Collaboration and Unity: Because the goal of effective supply chain inventory management is to make sure that the correct inventories are placed in the correct area at the right time, and there is smooth flow in departments of an organization or a company, this can be done only if departments and organizations work in collaboration and unity. This starts and ends with creating, maintaining, and nurturing a culture where departments work together and elevate each element of the supply chain.

Inventory Management Techniques

There are a variety of Inventory Management Techniques that businesses will use for their unique inventory needs.

ABC analysis – a technique that identifies the value of inventory items based on their importance to the business.

Batch tracking - practice through which businesses can trace and monitor the history of a group of items with similar properties as those items make their way through production and distribution channels, all the way to customers.

Bulk shipments demand forecasting - the process of using predictive analysis of historical data to estimate and predict customers' future demand for a product or service.

Drop shipping just-in-time inventory (JIT) - a management strategy that aligns raw-material orders from suppliers directly with production schedules. Companies employ this inventory strategy to increase efficiency and decrease waste by receiving goods only as they need them for the production process, which reduces inventory costs. This method requires producers to forecast demand accurately.

Lean manufacturing minimum order quantity - Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. Minimum Order Quantity (MOQ) refers to the minimum number of products or units that a supplier is willing to produce and sell and can be set per order, per product, per size or by color.

Cross-docking - Cross-docking is a practice in logistics of unloading materials from a manufacturer or mode of transportation directly to the customer or another mode of transportation, with little or no storage in between.

Conclusion

Knowing the differences between and applying the methods for inventory and supply chain management makes these strategies an essential part of your business plan to ensure customer satisfaction and business flexibility. Working with a qualified and experienced supply chain consultant will enable you to find the techniques best suiting for the unique needs of your business.

Final Thoughts

For more information on Inventory Management and Supply Chain Management topics, please click the link below:

DRIFT IQ LLC DBA T EXPONENTS™ PRIVATE, PROPRIETARY AND CONFIDENTIAL. COPYRIGHT © 2022 T EXPONENTS™. ALL RIGHTS RESERVED.